|

Today, there is clearly a movement under foot of the drag boat racer since my reintroduction of a forty-year-old technology, the twin propeller drive system for drag boats.

Back in the late 1950’s and early 1960’s, twin propeller drive propulsion systems made their début on drag boats with apparently little recognition of their potential to revolutionize drag boat racing.

Evidently, from what I have learned through my interviews with these pioneers (Bill Harrison, Herald Kindsvatter, and Larry Schwabeland) of forty years ago, there was little apparent realizable benefit of the twin drive as compared, then, to a single propeller drive. This in part, may be due to the significantly less available engine power then for drag boats as compared to today’s monster horsepower engines. In addition, as one of the stories is told, the requirement of continued development, in this case an increase of the overdrive ratio of the twin drive, necessitated a re-manufacture of a gear case. This was back in the days without computer aided manufacturing and would have taken months to re-manufacture. Consequently, it was just easier to abandon the twin drive in favor of the ease of implementing existing and available technology then, the V-Drive.

There was a lot of talk in the late 1980’sand early 1990’s by racers, and articles written about the potential value of a twin drive propeller system for the drag boats, but very little was done about actually implementing one until my reintroduction of the twin propeller drive system in1996 on my Nitro Bullet One drag boat.

I have dubbed this relatively new incarnation of the twin propeller drive transmission, the W-Drive. When looking down from the top of the W-Drive gearbox the input shaft forms, with respect to the output shafts, a stylized horizontal “W” shape. A W-Drive, by definition, is a unit construction transmission that contains a single input shaft and two counter rotating output shafts.

A W-Drive, by definition, is not to be confused with a twin propeller drive using three transmissions (a transfer gear box, and two V-Drives) lashed together to form a two-propeller drive system. I call this drive system a T2V drive.

There was considerable intuitive speculation in the late 80’s and early 90’s as to the potential benefits of the twin propeller drive, but very little was actually researched and known about how this drive system would behave in the context of drag boats, and in particular, for my interest at the time, the Top Fuel drag boats. For me, the question of the application of two propellers was answered after taking about six months of spare time in1993 and writing an engineering paper (unpublished)regarding The Forces That Act On A Rapid Accelerating Water Craft. This investigation revealed, through mathematics and applied physics, the basic behavior of a twin drive, and also illuminated that drag boats of today, or perhaps more appropriately stated, of yesterday, required redesign, or simply fell short of an ideal behavior in the context of rapid acceleration. My future series of articles in DBR will be an exposé on the findings during that investigation.

Now, why two propellers?

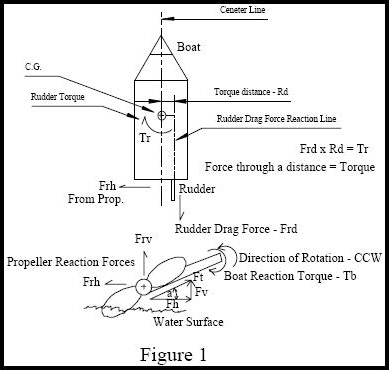

Figure 1 depicts a single propeller drive and the reactive (key word) forces and torques that act on a device (a boat) that attempts to restrain or harness the propeller motion in water. Ft is the thrust force along the propeller shaft and its horizontal component of force, Fh is what pushes the boat in the desired direction of motion. Frv is the reactive force of the propeller penetrating the water surface in the vertical direction and is only in play on the boat when it is underway, or, as is sometimes said, when the boat has “blown its tail”. Fv is the vertical component of propeller thrustforce and is what initially (blows the tail) lifts the boat out of the water and when added to Frv partially sum to the total force acting to lift the boat out of the water. Clearly, other forces are in play that lift the boat, such as the aero and hydrodynamic forces.

Frh, the “paddle wheel force” is the horizontal reactive force of the propeller paddling against the water and can be one of the most detrimental forces influencing the handling characteristics of a drag boat.

The propeller “force triangle” in figure 1 is derived from decomposing the Ft force vector into its horizontal, Fh, and vertical components, Fv. Angle “a” is formed between Ft, and Fh.

Now it becomes apparent that the force Frh (paddle wheel force) is undesirable because of the obvious potential effect of walking the back of the boat around the boats center of gravity (C.G.) and results in pushing the boat in a clockwise direction off its intended direction of motion. However, an appropriate amount of rudder angle can supply a counter acting force that will be equal and opposite of Frh and will result, ideally, in the boat going straight, more or less. However, the addition of corrective rudder creates a sizable amount of drag and can significantly reduce the performance of the boat.

The rudder being mounted off center onthe right side of the boat also adversely contributes a torque Tr by the application of the rudder drag force Frd through its offset mounting distance Rd that tends to pull the boat in a clockwise direction. From the above relationship, it can be seen that the single propeller boat would benefit in mounting its rudder off center on the left side of the boat. This could supply a beneficial torque in the opposite direction of Frh and, in part, counteract the” paddle wheel” force, Frh .

Could it be after all these years that drag boats have been setup with an adverse rudder position being on the right side of the centerline of the boat instead of the left?

Another major contributor of an undesirable force is the dreaded torque (a force through a distance) Tb that is a result of a single propeller’s rotation reaction to water. This single propeller torque in a Top Fuel drag boat can actually revolve the boat around the propeller, resulting in turning the boat over, just off the starting line. I actually saw this happen in Chowchilla California in 1997. Other less dramatic responses to the torque Tb are (1) the driving of the right sponson into the water, creating additional drag, and (2) lifting the left sponson in the air, resulting in handling problems. Most drag boat builders will put weight in the left sponson to help control the handling problems that result in decreased performance due to increased weight.

What is needed is an efficient system of propulsion that does not have all the undesirable effects described above.

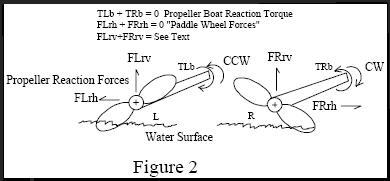

Figure 2 illustrates a twin counter rotating propeller drive system. Note the propeller direction of counter rotation and the corresponding propeller horizontal reaction forces and torques. The horizontal forces FLrh and FRrh (paddle wheel forces) are equal, and opposite in direction and magnitude, and therefore cancel themselves through the propeller strut mechanical connection to the boat. Likewise, the boat reaction torques TLb and TRb about each propeller shaft also cancel each other because of the counter rotation of the propellers. The result of these intrinsic force and torque cancellations is a propulsion system with most of the undesirable effects of the propeller reaction to water removed. Figure 2 illustrates a twin counter rotating propeller drive system. Note the propeller direction of counter rotation and the corresponding propeller horizontal reaction forces and torques. The horizontal forces FLrh and FRrh (paddle wheel forces) are equal, and opposite in direction and magnitude, and therefore cancel themselves through the propeller strut mechanical connection to the boat. Likewise, the boat reaction torques TLb and TRb about each propeller shaft also cancel each other because of the counter rotation of the propellers. The result of these intrinsic force and torque cancellations is a propulsion system with most of the undesirable effects of the propeller reaction to water removed.

When the propellers are properly phased at ninety degrees to each other, the propeller blade lift (FLrv and FRrv), due to the propeller blade’s reaction to the surface entry of the water, can be reduced by thirty percent.

An actual illustration of the cancellation of forces can be seen in a real life drama when my Nitro Bullet 3 lost its rudder at 210 M.P.H. at the IHBA World Finals in the year 2000 with no apparent effect on the boat’s direction of motion. It simply continued to run as straight as an arrow without its rudder.

|

Nitro Bullet Rudder Detaching at 220 MPH

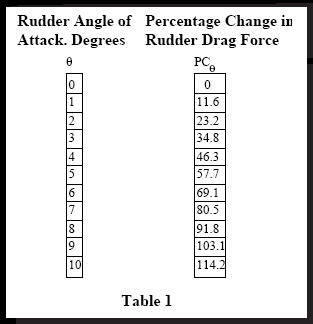

A major and often-overlooked water drag component of a drag boat is its rudder. The drag boat’s rudder, even in its most ideal center position, can drag as much as a couple of thousand pounds at 220 M.P.H. Drag forces increase dramatically as the rudder angle is increased from its position of minimal drag. Table 1 illustrates the dramatic percentage increase in drag force caused by a rudder as a function of an increase in the rudder angle of attack. A major and often-overlooked water drag component of a drag boat is its rudder. The drag boat’s rudder, even in its most ideal center position, can drag as much as a couple of thousand pounds at 220 M.P.H. Drag forces increase dramatically as the rudder angle is increased from its position of minimal drag. Table 1 illustrates the dramatic percentage increase in drag force caused by a rudder as a function of an increase in the rudder angle of attack.

It can be observed from Table 1 that just nine degrees of rudder can more than double the amount of drag from the rudder as compared to its neutral position of minimal drag.

The W-Drive equipped drag boat with its rudder mounted on the center line of the boat will allow the rudder to assume the least drag position (no drive line forces to counter act) and consequently provides the maximum available force to accelerate the boat.

The W-Drive and its ability to intrinsically cancel undesirable forces along with proper propeller location contributes significantly to the stability of the drag boat at the starting line launch, and at the top end of the race course.

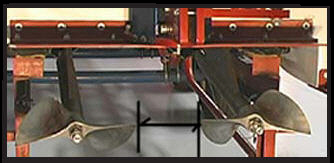

A common problem of the early twin drives, as well as some that you see today, is the close placement of the propeller axis of rotations. This close placement results in a smaller platform of stability, and reduction in efficiency of the propellers due to the turbulent interaction of one propeller to the other. Experience has shown that a tip-to-tip inner spacing of the propellers blades should be at least four tofive inches. One could argue that the further you place the propellers apart the more there would be a torque to turn the boat if one of the propellers is lost or damaged. This has been a major question and subject of much unfounded pessimistic speculation. However, experience has shown on the Wildside Top Fuel Hydro operating with centers of propeller rotation of eighteen inches (tip-to-tip innerspacing for a 11.5 inch prop of 6.5 inches) lost a propeller with very little effect on its stability. The advantage of a wide stance of the propellers provides significant benefitover the narrow position propellers. This topic of propeller spacing, preferred direction of propeller rotation, propeller timing, and the effects on stability will be explored in the future series of DBR articles.

Now therefore, Why Two Propellers? We can conclude from actual experience, or infer, from the above the following:

- Efficiency. The intrinsic nature of the W-Drivein its ability to cancel the “paddle wheel” reactive forces(Frh) and the boat reaction torque effects (Tb) of the propeller allows the rudder to remain more or less straight. The straight rudder minimizes the potential drag effect ofthe rudder. Minimal rudder drag translates into more available thrust force that increases performance. Center mounting of rudder eliminates offset rudder boat torque that also translates into better performance. All classes of boats can benefit from the increase in efficiency of a W-Drive. It would simply be a matter of degrees.

- SAFETY. Real world experience has demonstrated that a twin propeller top fuel drag boat can actually operate safely without a rudder as well as with a missing or damaged propeller. This safety can also apply to all other classes of boats from TFH to River Racer.

- Performance. It has been demonstrated in actual practice that the twin propeller drive can efficiently couple high horsepower engines to the water. The results speak for themselves; a new Top Fuel world record was set. It should be noted, you can lose a portion of the performance advantages of a twin drive with propellers spaced too closely together.

- Stability. The drag boat’s stability is significantly enhanced both at the starting line and at the top end of the track, due primarily to the cancellation ofthe propeller reactive torque and ”paddle wheel” forces. Proper propeller spacing, direction of rotation, and timing can enhance the stability of a drag boat. I would like to recognize Bill Harrison of Hemi Engineering. Before his death in 1993, he had a major influence on my early work with the twin propeller drive.

|